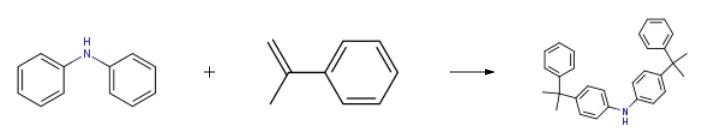

Bis[4-(2-phenyl-2-propyl)phenyl]amine synthesis

- Product Name:Bis[4-(2-phenyl-2-propyl)phenyl]amine

- CAS Number:10081-67-1

- Molecular formula:C30H31N

- Molecular Weight:405.57

a, first raw material diphenylamine 50.0g into a reaction vessel equipped with a stirrer, reflux condenser, heated to diphenylamine added to melt;After completely melted, a mixed catalyst prepared from 1.5 g of magnesium chloride and 1.5 g of anhydrous stannous chloride was added, and heating and stirring were continued for mixing; b. After step a is mixed uniformly, 80.5 g of α-methylstyrene is added dropwise, and the dropwise addition time is 0.5 h. After the dropwise addition is completed, the reaction temperature is controlled to be 130-140° C., and the reaction is completed at this temperature for 1 h. The reaction is completed. ; c, after the end of the reaction, the resulting reaction solution was cooled, then add 60 of petroleum ether 140g and methanol 5g mixed solvent, dropped to 25 ± 2 °C cooling crystallization; d, after the end of crystallization, followed by filtration, petroleum ether and water washing, and then dried at 45 °C for 14 hours, dried to obtain the antioxidant 4,4 '- bis (α, α- dimethyl benzyl) diphenylamine . The product obtained in this example was white crystal with a yield of 85% and a purity of 98.24%

122-39-4

345 suppliers

$14.00/5g

98-83-9

312 suppliers

$10.00/25mL

![Bis[4-(2-phenyl-2-propyl)phenyl]amine](/CAS/GIF/10081-67-1.gif)

10081-67-1

211 suppliers

$9.00/5g

Yield:10081-67-1 85%

Reaction Conditions:

Stage #1:diphenylamine with tin(ll) chloride;magnesium chlorideHeating;

Stage #2:isopropenylbenzene at 130 - 140; for 1.5 h;Reagent/catalyst;Temperature;

Steps:

4 Example 4:

a, first raw material diphenylamine 50.0g into a reaction vessel equipped with a stirrer, reflux condenser, heated to diphenylamine added to melt;After completely melted, a mixed catalyst prepared from 1.5 g of magnesium chloride and 1.5 g of anhydrous stannous chloride was added, and heating and stirring were continued for mixing; b. After step a is mixed uniformly, 80.5 g of α-methylstyrene is added dropwise, and the dropwise addition time is 0.5 h. After the dropwise addition is completed, the reaction temperature is controlled to be 130-140° C., and the reaction is completed at this temperature for 1 h. The reaction is completed. ; c, after the end of the reaction, the resulting reaction solution was cooled, then add 60 of petroleum ether 140g and methanol 5g mixed solvent, dropped to 25 ± 2 °C cooling crystallization; d, after the end of crystallization, followed by filtration, petroleum ether and water washing, and then dried at 45 °C for 14 hours, dried to obtain the antioxidant 4,4 '- bis (α, α- dimethyl benzyl) diphenylamine . The product obtained in this example was white crystal with a yield of 85% and a purity of 98.24% (see FIG. 4 for details).

References:

Weilin New Materials Technology Co., Ltd.;Xu Zhisong;Guo Deyi;Li Hongxi;Song Fengchao;Wang Fei;Qu Junwei;Wang Zhiqiang;Guo Tongxin;Qian Juanjuan;Duo Yankui CN107540559, 2018, A Location in patent:Paragraph 0020; 0036-0070